When you dive into fiber optic industry, You have to have better understanding about fiber optic connectors. they are of different types and characteristics. Here you are in the right place to have a complete idea about fiber connectors.

What is fiber optic connector?

A fiber optic connector also goes by the name termination because it connects two ends of fiber optic cables. These connectors hold the fiber optic cables together inside the ferrule to attach them to the other side of the cables. Ferrules are the connector end pieces that include the method of connecting and securing the termination. Some ferrules will plug into a mating adapter and screw to hold the two portions together. Others use a bayonet design, while some snap together.

Some ferrules have a spring-loaded connector to hold the pieces together with constant force for improved connection. Most fiber optic connectors require effort to connect and disconnect, reducing the chances of accidentally pulling the cables apart during typical use or installation of other components. Connectors can also bring a cable into a converter or directly into the device serviced by the fiber optic cable.

Types of fiber optic OFC connectors

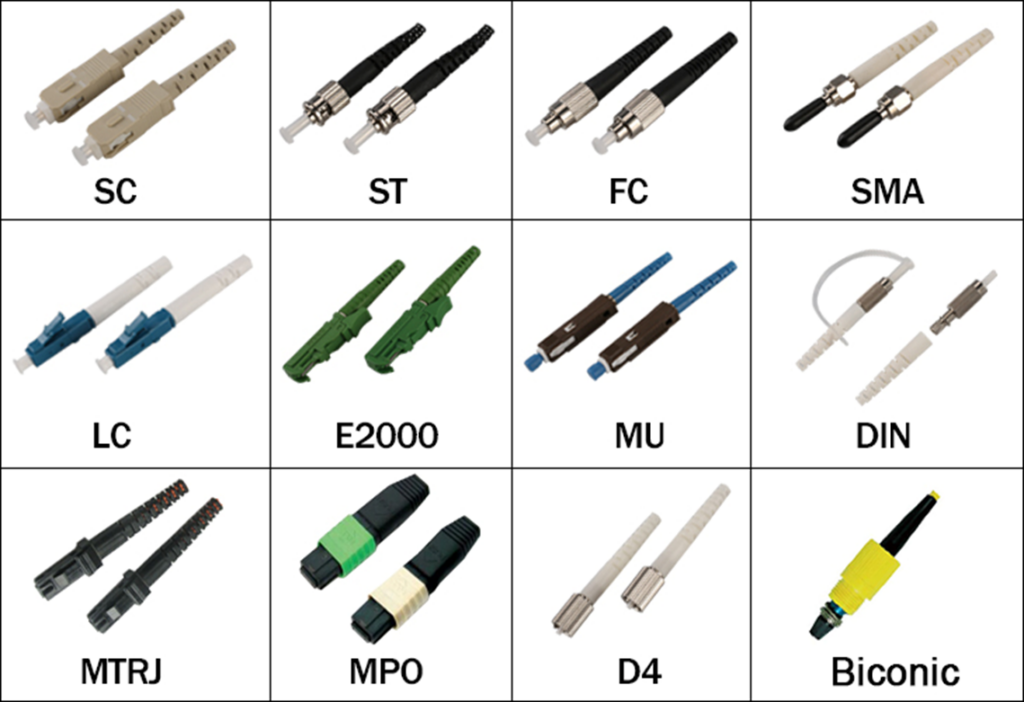

As below you can see the outer appearance about the fiber optic connectors, SC, LC, FC, ST fiber connectors are the most common types in fiber optic connection.

Comparasion OFC Optical connectors

| Connector Type | Ferrule Diameter (mm) | Mode | Insertion Loss (Typical) | Return Loss (Typical) | Key Features |

|---|---|---|---|---|---|

| LC (Lucent Connector) | 1.25 | Singlemode/Multimode | 0.1 – 0.5 dB | >50 dB | Small form factor, high-density, push-pull mechanism |

| SC (Subscriber Connector) | 2.5 | Singlemode/Multimode | 0.2 – 0.5 dB | >50 dB | Snap/push-pull mechanism, commonly used in datacom/telecom |

| ST (Straight Tip) | 2.5 | Singlemode/Multimode | <0.5 dB | >50 dB | Bayonet-style coupling, commonly used in multimode apps |

| FC (Ferrule Connector) | 2.5 | Singlemode/Multimode | 0.2 – 0.5 dB | >50 dB | Screw-on mechanism, precise alignment, telecom use |

| MTP/MPO (Multi-fiber Termination Push-on/Pull-off) | N/A | Singlemode/Multimode | 0.35 dB (typical for MPO) | Variable | Multi-fiber, high-density applications, data centers |

| MU (Miniature Unit) | 1.25 | Singlemode/Multimode | 0.2 – 0.3 dB | >50 dB | Miniaturized SC connector, compact environments |

| MT-RJ (Mechanical Transfer-Registered Jack) | N/A | Singlemode/Multimode | <0.5 dB | >40 dB | Dual-fiber connector, small form factor, RJ-45-like |

| E2000 | 2.5 | Singlemode/Multimode | 0.1 – 0.5 dB | >50 dB | High safety standards, integrated dust cap |

| SMA (SubMiniature version A) | 3.14 | Multimode | 1.0 dB | Low | Industrial and military applications |

| FDDI (Fiber Distributed Data Interface) | 2.5 | Multimode | 0.5 dB | Variable | Used in FDDI networks, similar to ST but with a pin |

| ESCON (Enterprise Systems Connection) | 2.5 | Multimode | 0.5 dB | >30 dB | IBM mainframe networks, duplex connector, retractable shroud |

Components of fiber optic connectors

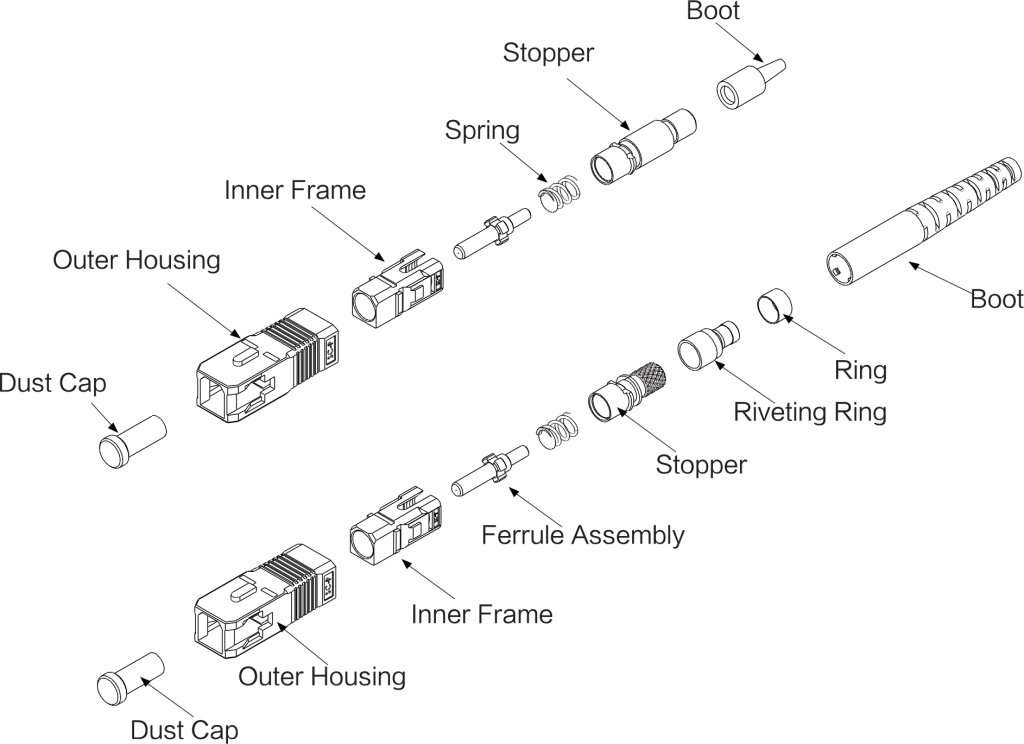

There are three major components of a fiber connector: the ferrule, the connector body, and the coupling mechanism. Take SC fiber connectors for example.

- Ferrule: this is a thin structure (often cylindrical) that actually holds the glass fiber. It has a hollowed-out center that forms a tight grip on the fiber. Ferrules are usually made from ceramic, metal, or high-quality plastic, and typically will hold one strand of fiber.

- Connector Body: this is a plastic or metal structure that holds the ferrule and attaches to the jacket and strengthens members of the fiber cable itself.

- Coupling Mechanism: this is a part of the connector body that holds the connector in place when it gets attached to another device (a switch, NIC, bulkhead coupler, etc.). It may be a latch clip, a bayonet-style nut, or similar device.

Fiber optic connectors Explained

Firstly, You can refer to the fiber connectors tables to learn the difference in general.

| Name | Mating Cycles | Ferrule Size | Typical Insertion Loss (db) | IEC Spec | Application Features |

| SC | 1000 | Ø2.5mm Ceramic | 0.25 – 0.5 | 61754-4 | Mainstream, Reliable, Fast deployment, Field fit |

| LC | 500 | Ø1.25mm Ceramic | 0.25 – 0.5 | 61754-20 | High density, Cost effective, Field fit |

| FC | 500 | Ø2.5mm Ceramic | 0.25 – 0.5 | 61754-13 | High precision, Vibration environments, Field fit |

| ST | 500 | Ø2.5mm Ceramic | 0.25 – 0.5 | 61754-2 | Military (legacy), Field fit |

| MPO | 1000 | 6.4 x 2.5 mm Composite | 0.25 – 0.75 | 61754-7 | High density, Aggregate networking, Fast deployment |

The most commonly used connectors today are ST, SC, FC, MT-RJ, & LC connectors while Plastic FOC, Opti-Jack, LX-5, Volition, MU, and E2000 are less used options. Finally, MPO / MTP connectors are fiber connectors that have become widely used in today’s data centers.

SC Connector

The SC is a snap-in connector which also features a 2.5mm ferrule much like the ST connector and is known for its excellent performance. The connector is simple, rugged, and low cost. Its simple push on/pull off operations makes it a popular choice.

ST Connector

The ST connector remains one of the most widely used connectors especially for multimode networks such as college campuses and most buildings. The connector is very easy to use due to its spring-loaded, keyed, and “push in and twist” mechanism within its design. The ST connector features a bayonet mount and a long cylindrical 2.5mm ceramic or polymer ferrule to hold the fiber.

Ferrule Core (FC) Connector

The FC connector was widely popular within fiber optic networks however its use has been dwindling in recent times replaced with SC and LC. The connector uses a threaded container and aligned key. Once positioned it can remain in place with perfect precision.

MT-RJ

The MT- RJ is a duplex connector where both fibers are in a single polymer ferrule. It utilizes pins for alignment and has male, female, and plug and jack formats. The MT-RJ is a duplex and is often difficult to test, as most test sets do not allow direct adaption to the connector.

Lucent Connector (LC)

The LC connectors are highly popular within single mode networks. It is known for good performance and small size. LC connectors have a 1.25mm ferrule, approximately half the size of SC connectors. It’s also commonly referred to as the “little connector”.

MU

MU connectors resemble a miniature version of SC with a 1.25mm ferrule. Its small size allows the MU connector to have a reduced footprint and are used in dense applications. The connector is square and uses a push-pull mechanism to lock. This type of connector is more popular in countries such as Japan.

E2000 Connector

The E2000 connector is mainly used in modern telecommunication networks. The connector features a unique spring-loaded shutter that protects the ferrule from dirt, dust, and scratches. Since the connector uses a monobloc ceramic ferrule, problems related to different co-efficient of expansion are nonexistent. The E2000 utilizes a push-pull locking connector. The E2000’s return loss is one of the lowest in the industry at just 0.1 db.

MPO/MTP Connectors

MPO or MTP terminated cables are widely used in high-density cabling environments like data centers. Traditional, tight-buffered multi-fiber cable needs to have each fiber individually terminated by a skilled technician. MPO cable which carries multiple fibers comes pre-terminated. Factory terminated MPO / MTP connectors commonly have either 12 fiber or 24 fiber array. MPO stands for Multi-Fiber Push On. This connector is commonly used to terminate multi-fiber ribbon connections in indoor environments. To the naked eye, there is very little difference between the two connectors.

fiber optic connectors polishing types

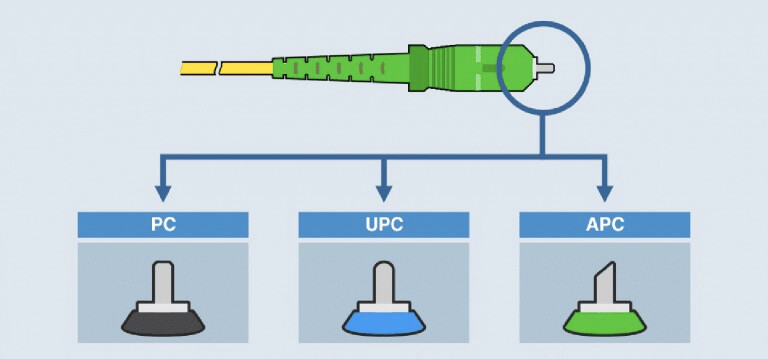

- PC: Physical Contact. The ferrule is beveled and finished in a plain surface. This avoids empty spaces between the ferrules of the connectors being coupled, and achieves insertion losses among -30 dB and -40 dB. Its use is increasingly falling out.

- UPC: Ultra Physical contact. They are similar to the PC connectors, allowing decreasing return losses to a margin between -40 and -55 dB thanks to the sharper curve of the bevel. The current trend is using it in dead lines to allow operators to perform networks tests for example by using an OTDR.

- APC: Angled Physical Contact. The ferrule ends in a plain, 8 degree angled surface making it the connector that achieves a best optical link because it cuts down the return losses up the -60 dB thus allowing increasing the number of users in single mode fibers. For this reason, combined to its constantly decreasing manufacturing costs, APC has become the most used polishing type.

fiber optic connectors polishing types

With so many different types and suitability, You should know the differences to identify connectors, Herewith the table to keep in mind.

| Fiber Cable | Connector Body |

| 62.5/125 | Beige |

| 50/125 | Black |

| 50/125 laser optimized | Aqua |

| OM5 | Lime |

| Single mode | Blue |

| Single mode with APC polish | Green |

How to Choose the Right Fiber Connectors?

The differences between types of connectors can easily be overlooked in the complex planning around fiber deployments. However, taking the time to select the right one for the job can deliver big benefits when it comes to speed and cost, so take the time to investigate your options before making your connector choice.

With the above knowledge and taking the below factors into consideration. Then you can have a wise choice for your projects.

- Single mode or Multimode

- UPC or APC Polishing types

- Simplex or Duplex

Conclusion

As a professional supplier of fiber optic, Bativ offers a comprehensive portfolio of fiber optic cables with different connector types. They all have passed the industry standard test to deliver optimal performance and reliability.